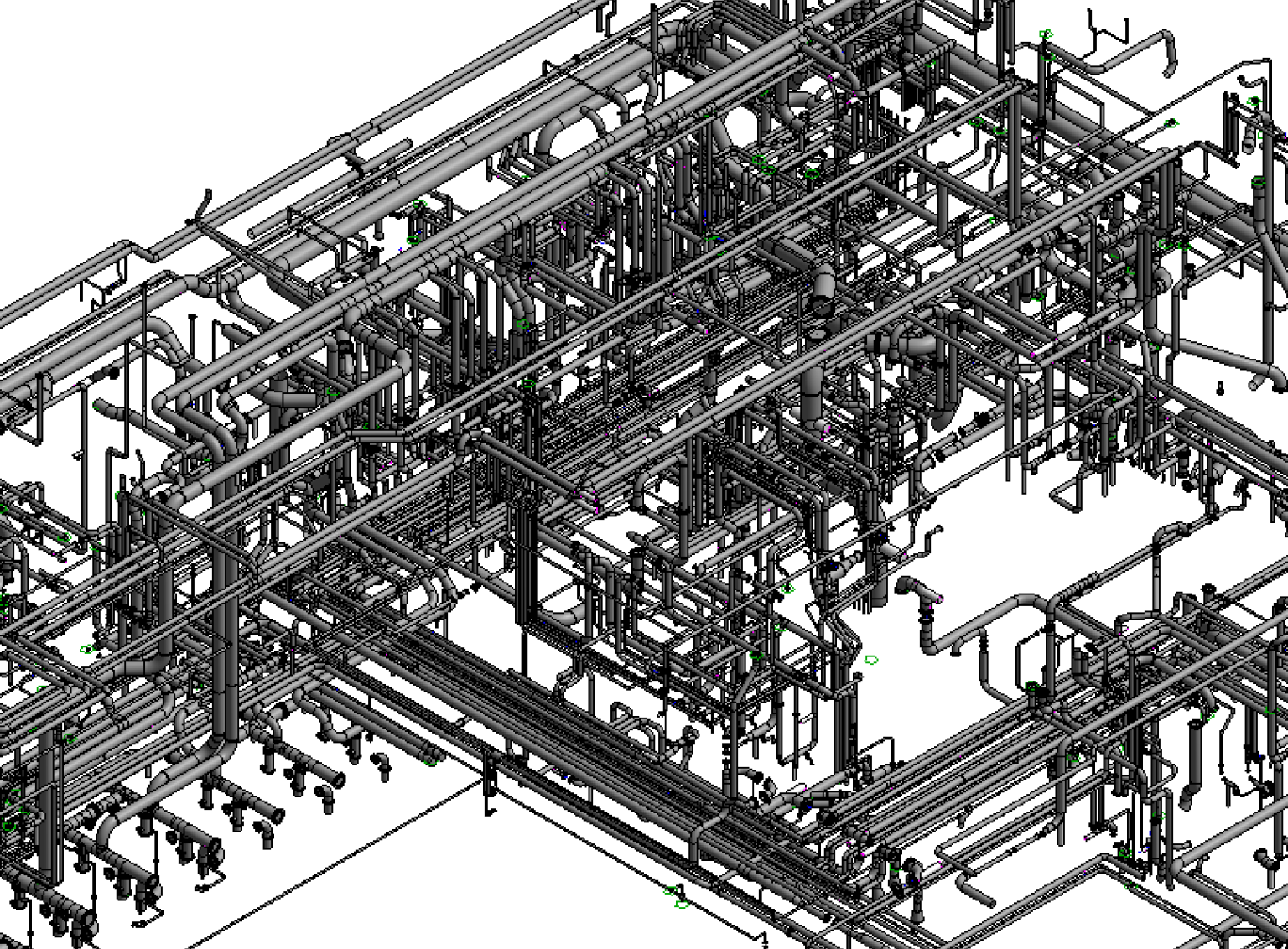

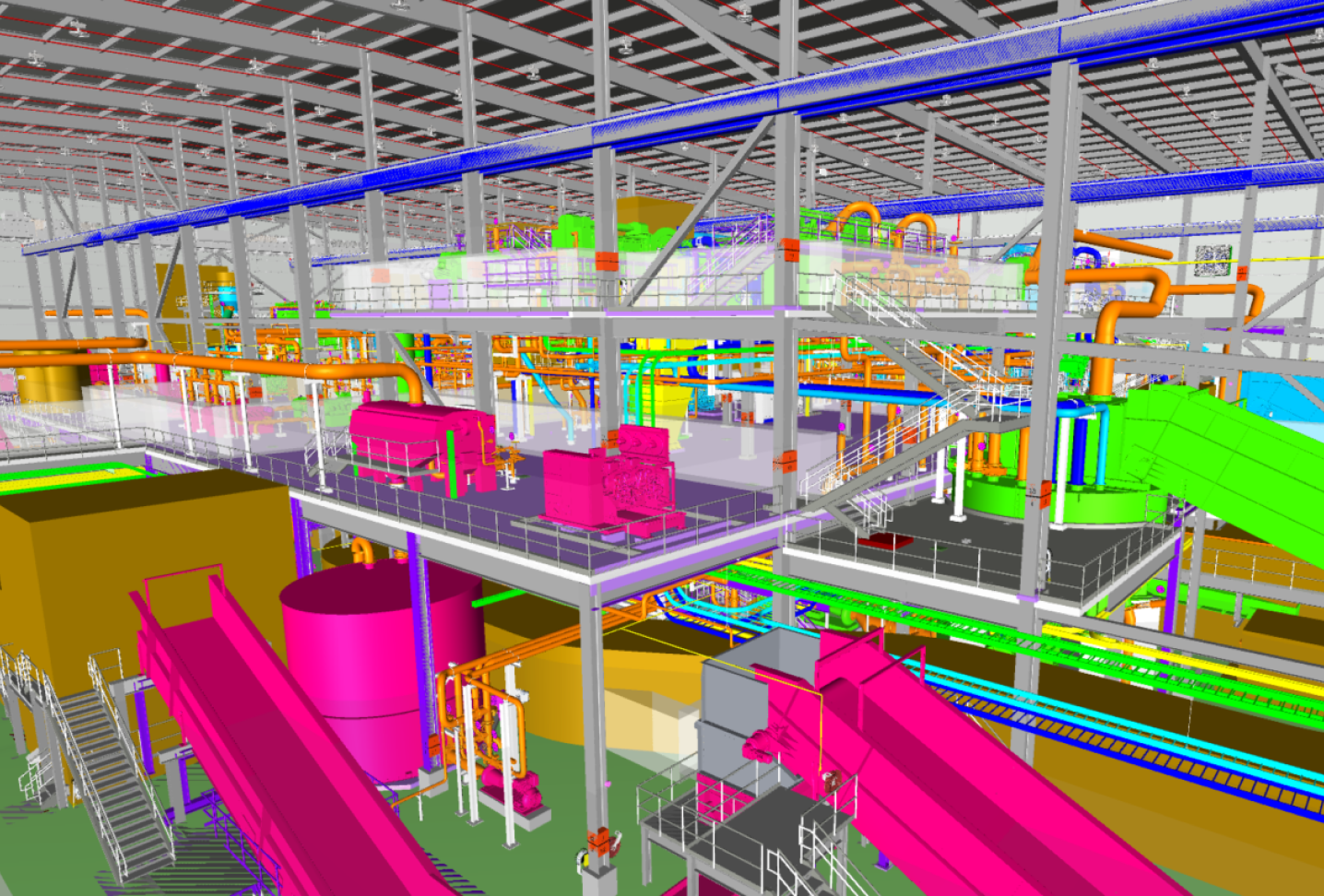

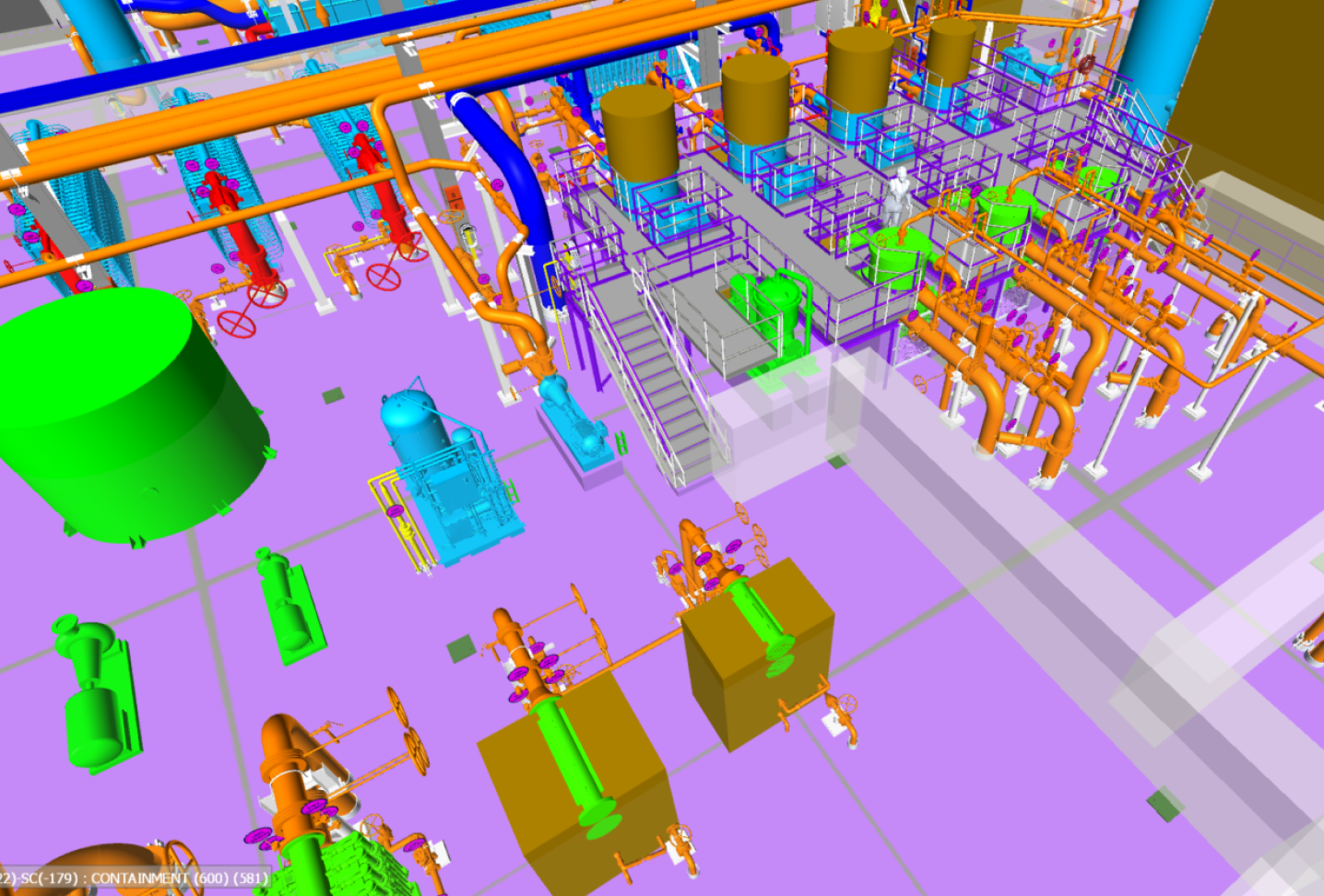

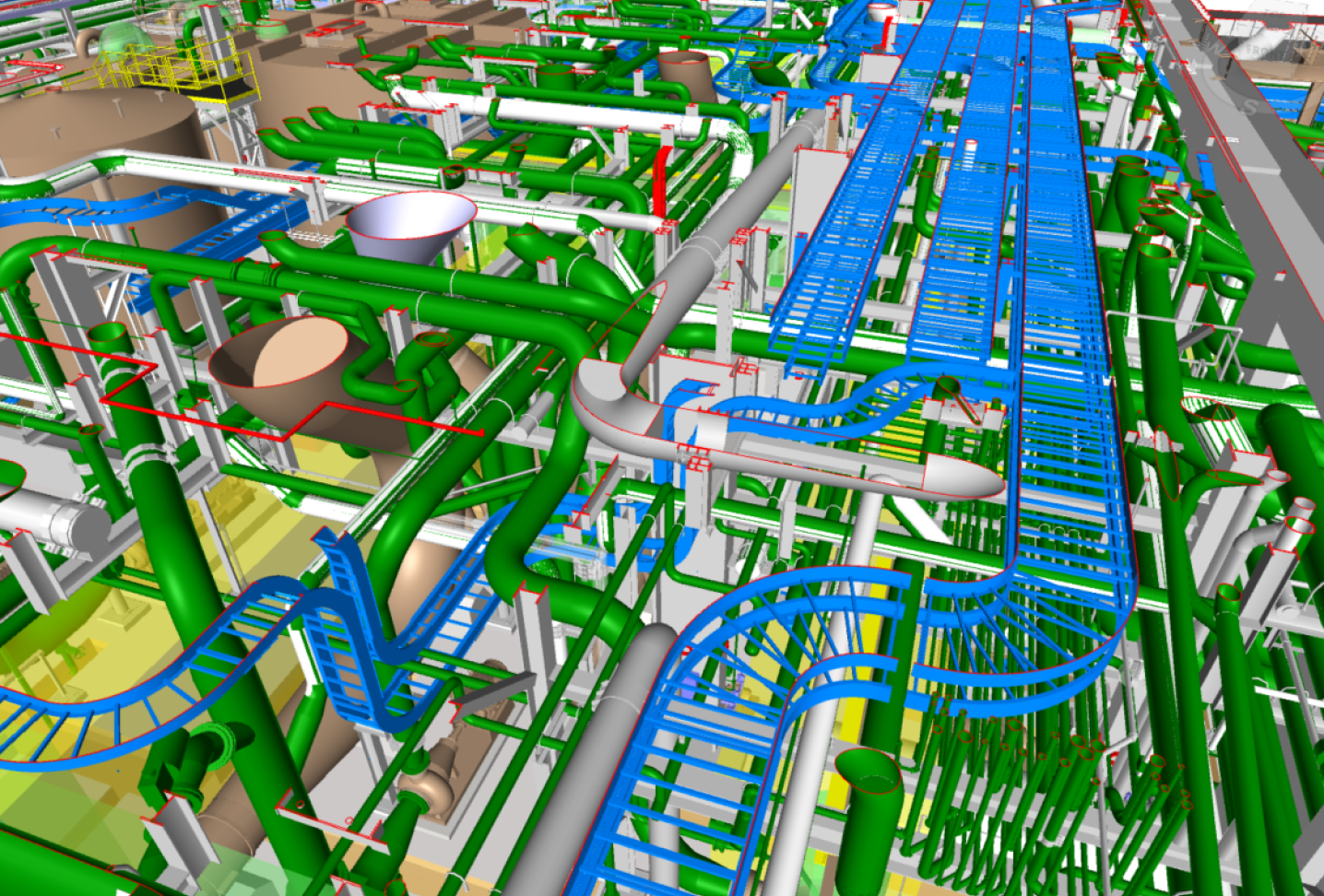

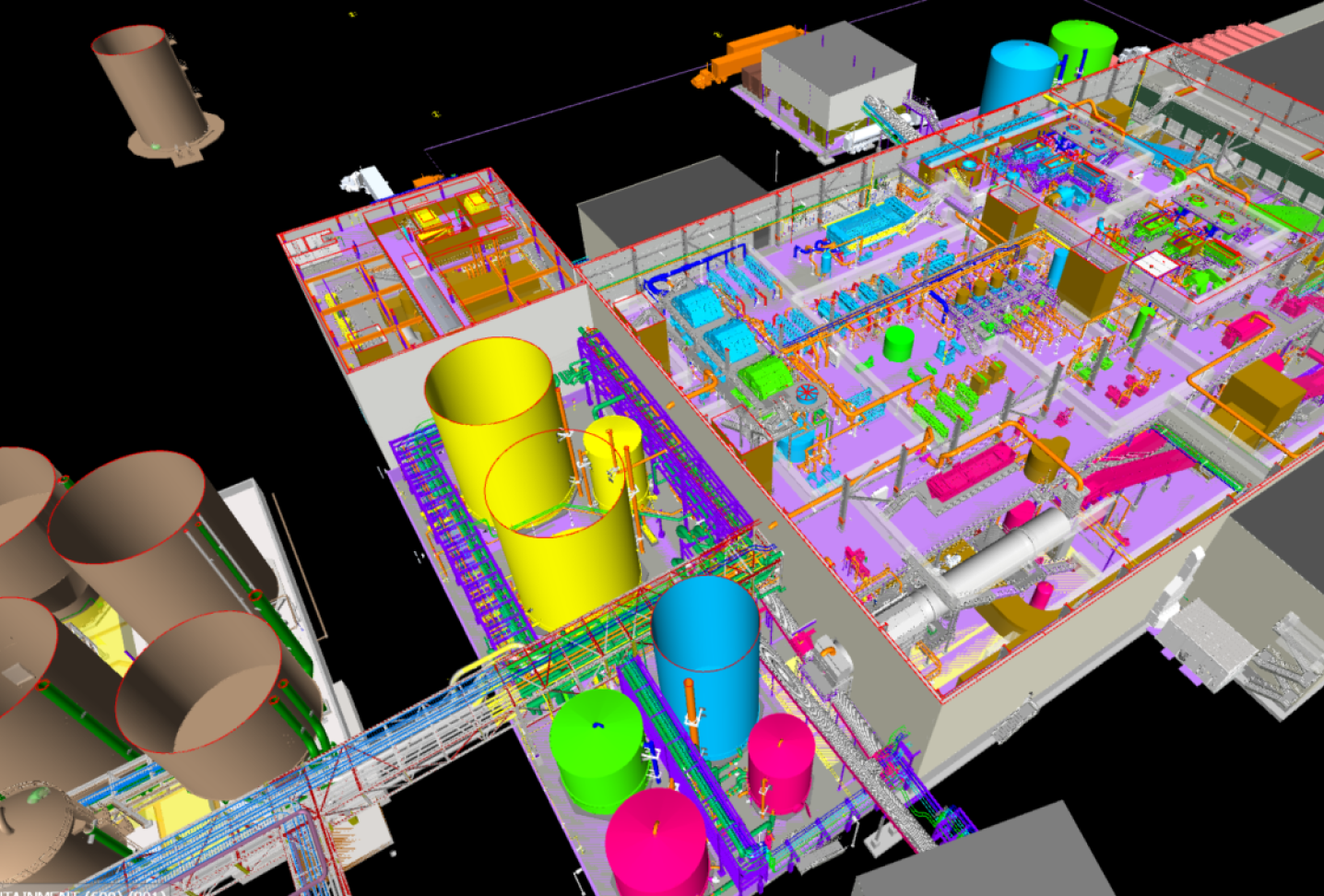

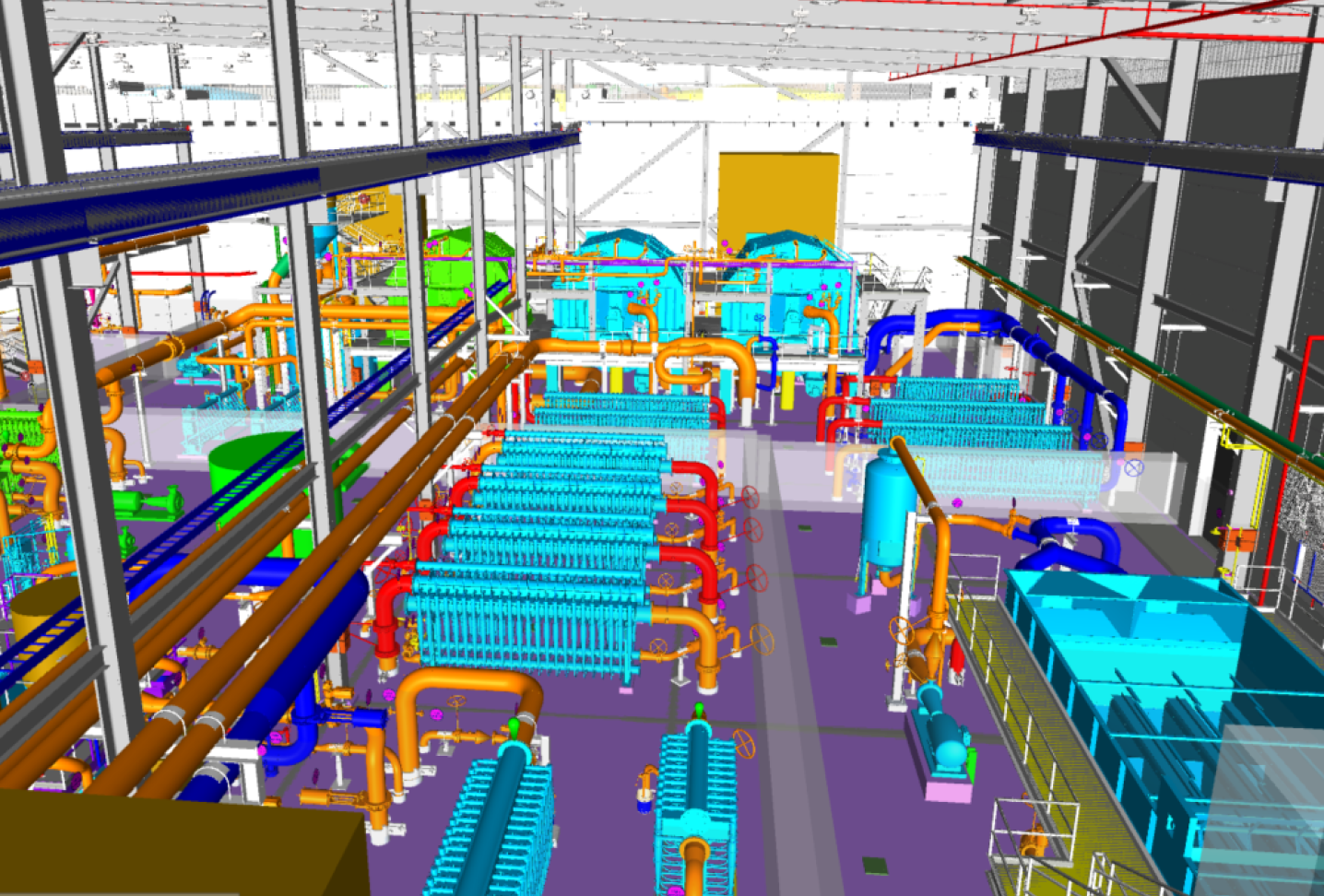

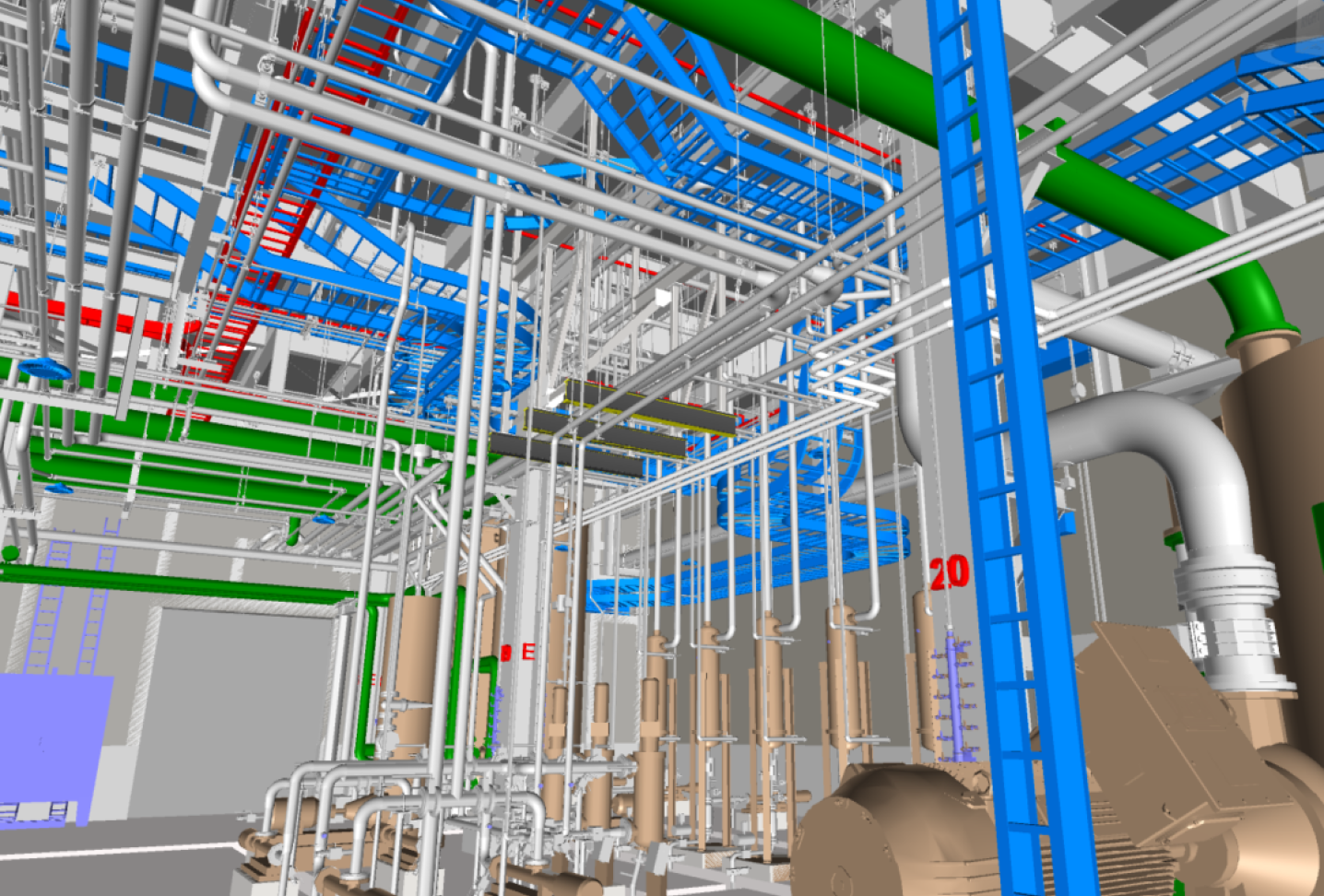

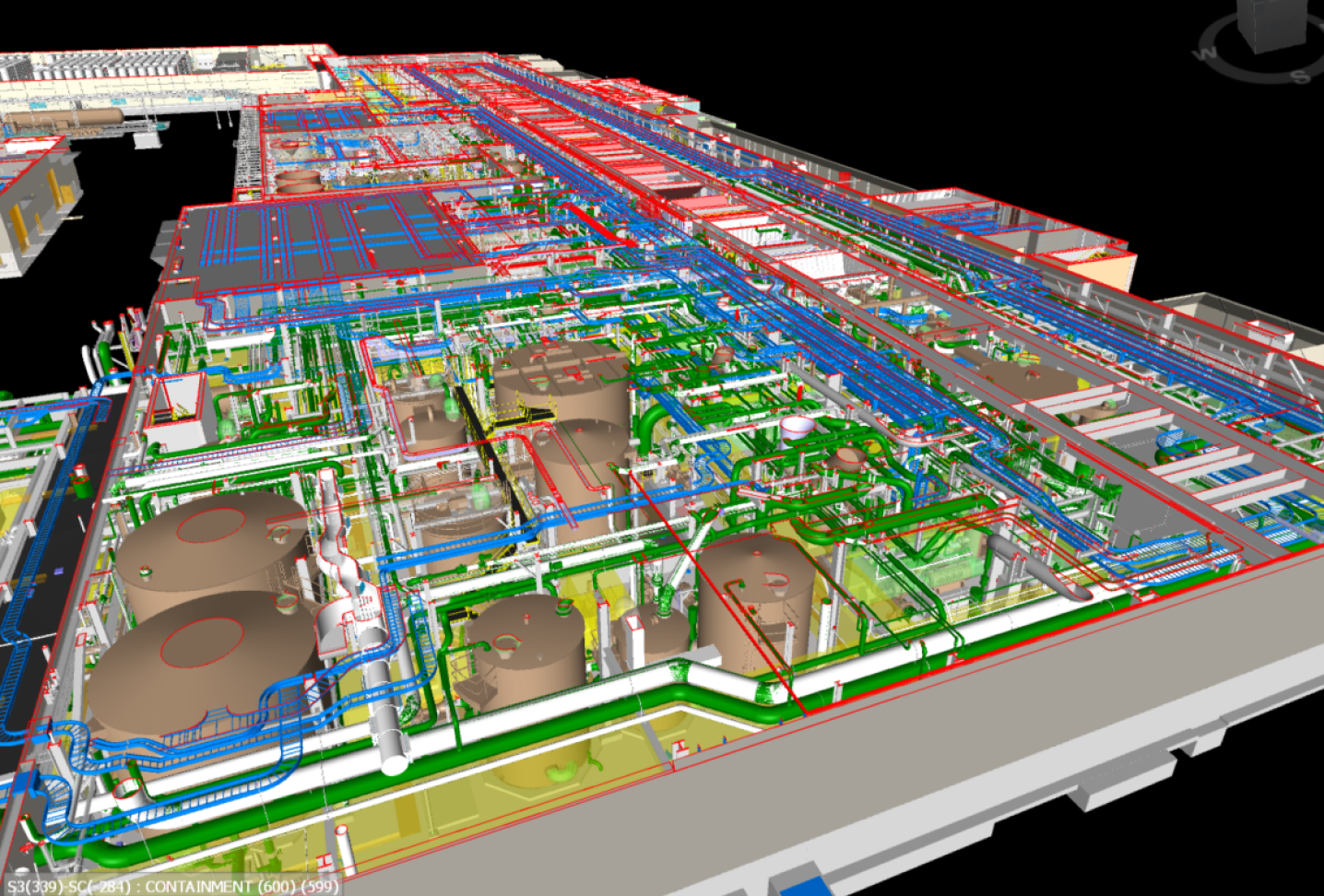

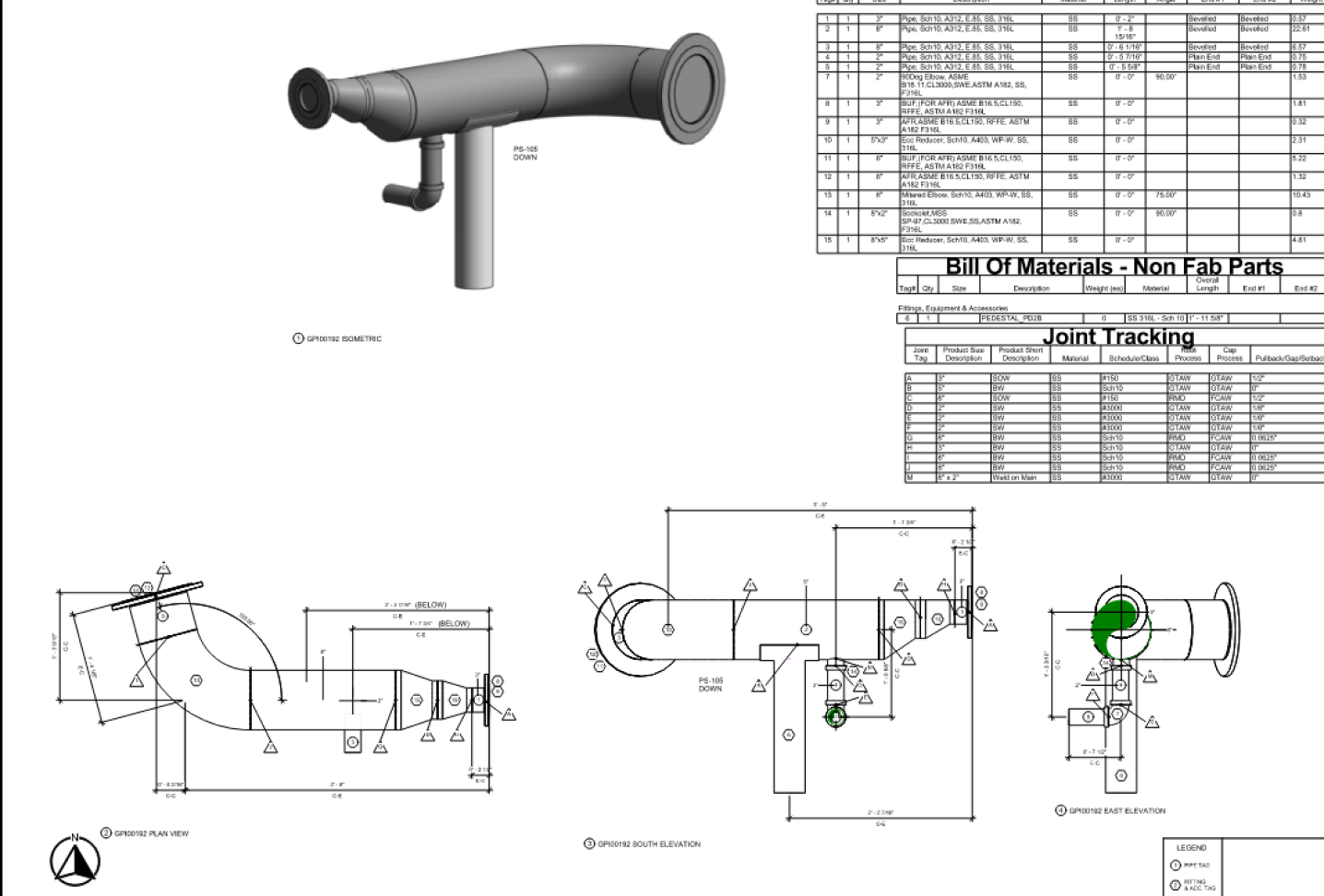

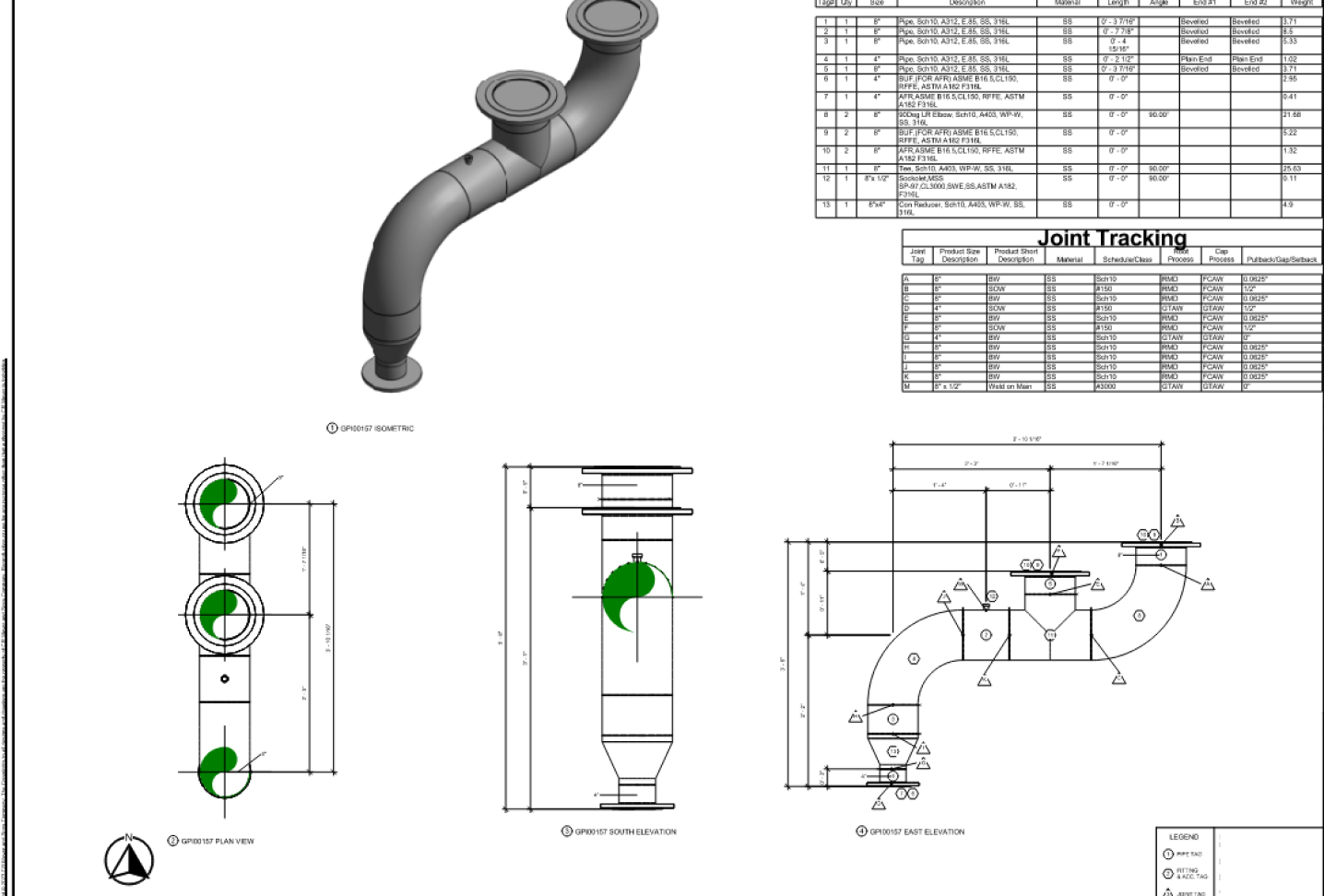

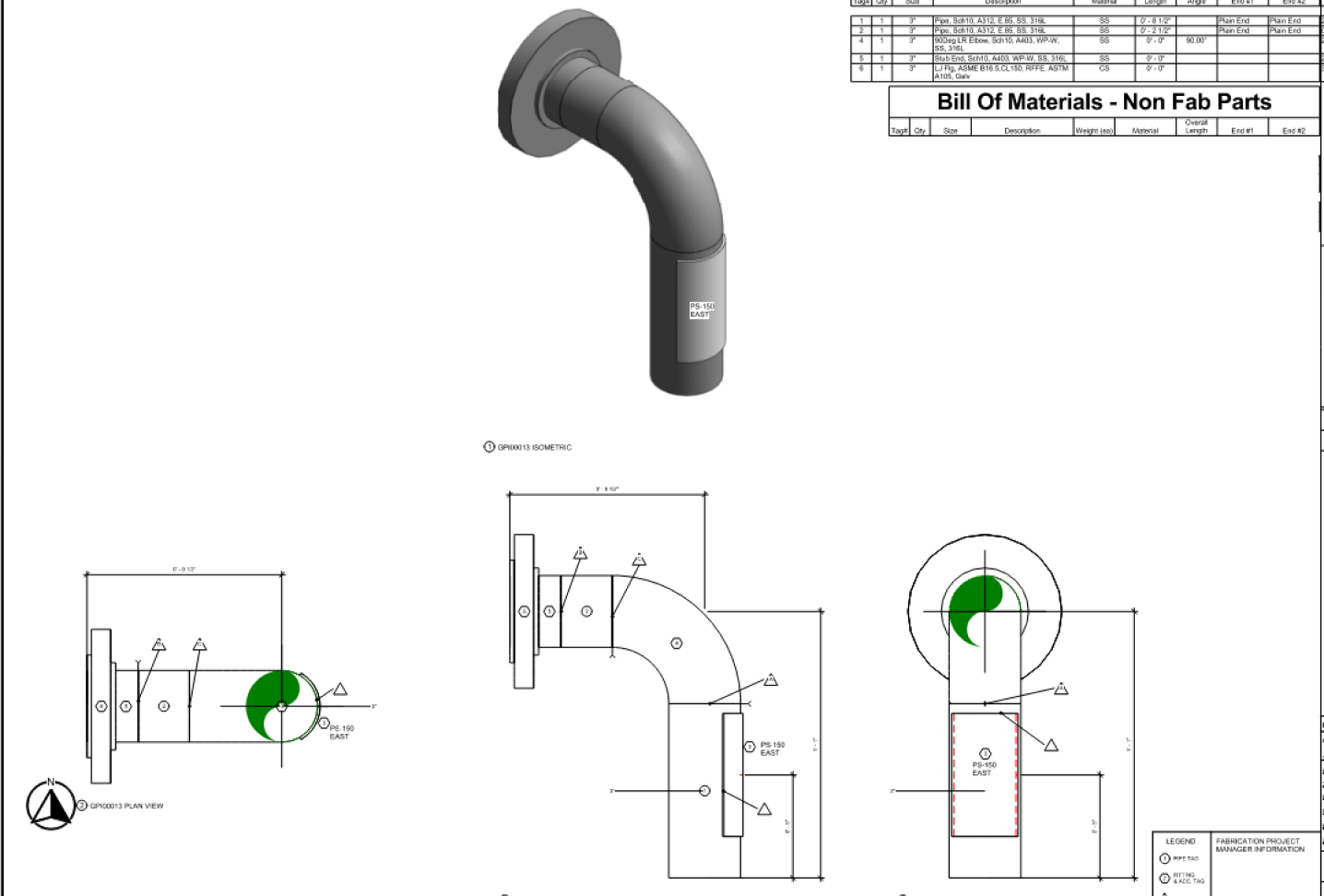

Industrial pipework modelling for a paper plant, featuring +15 systems, 140,000 linear feet of diverse diameter pipes (2-1/2" to 48"). Focus on prefabrication (LOD 400), spooling, and use of fabrication parts with 1/16" tolerance.

Project overview

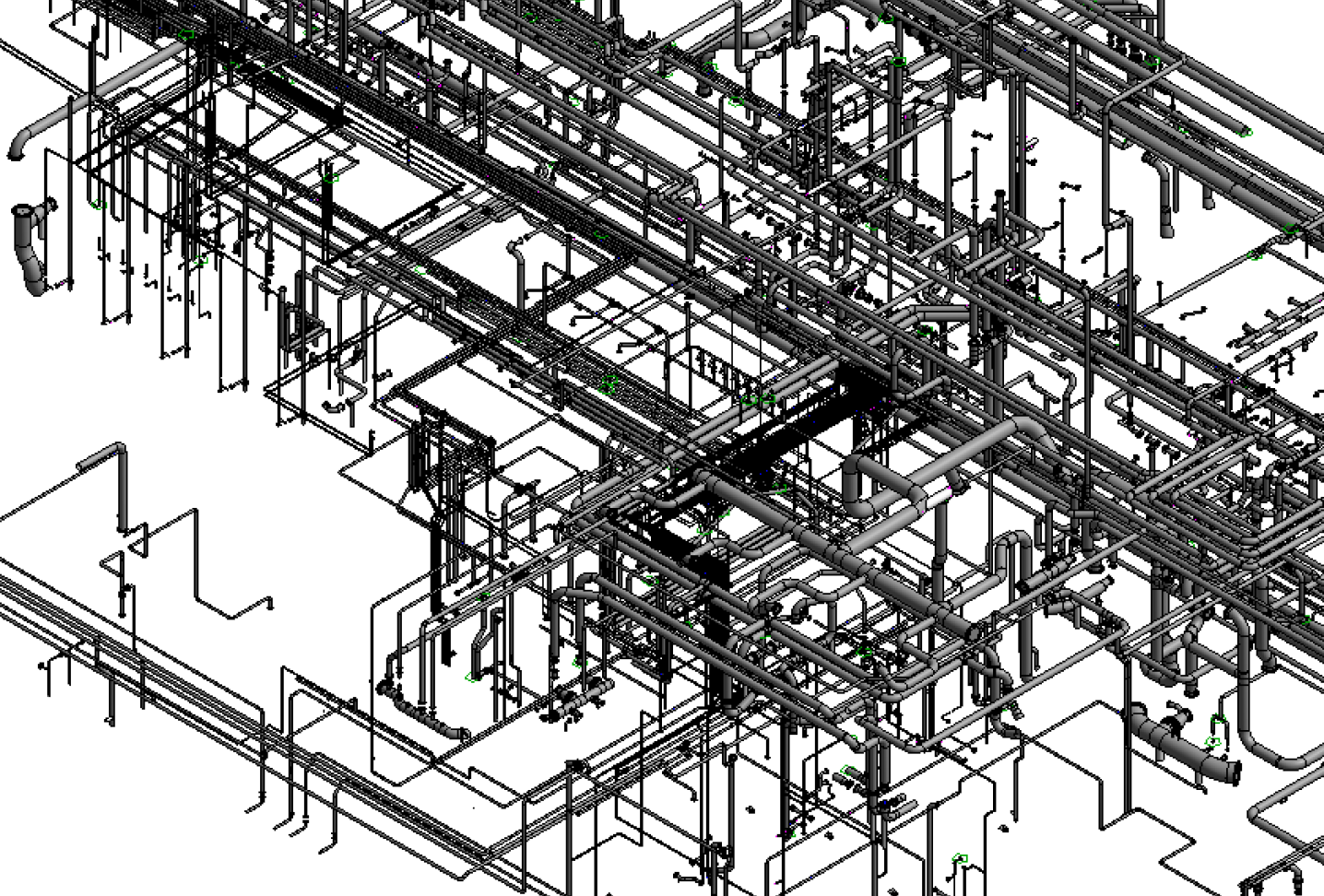

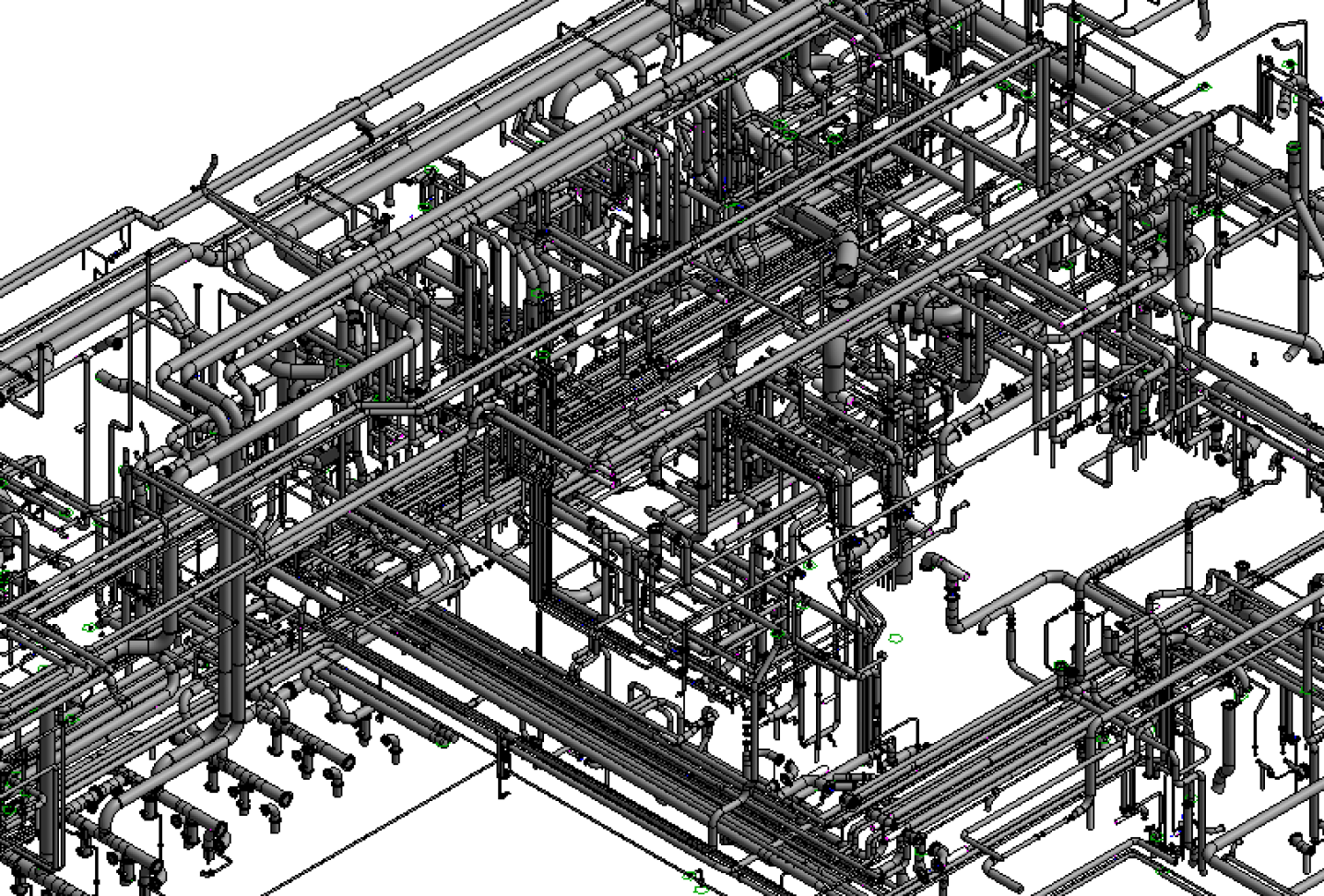

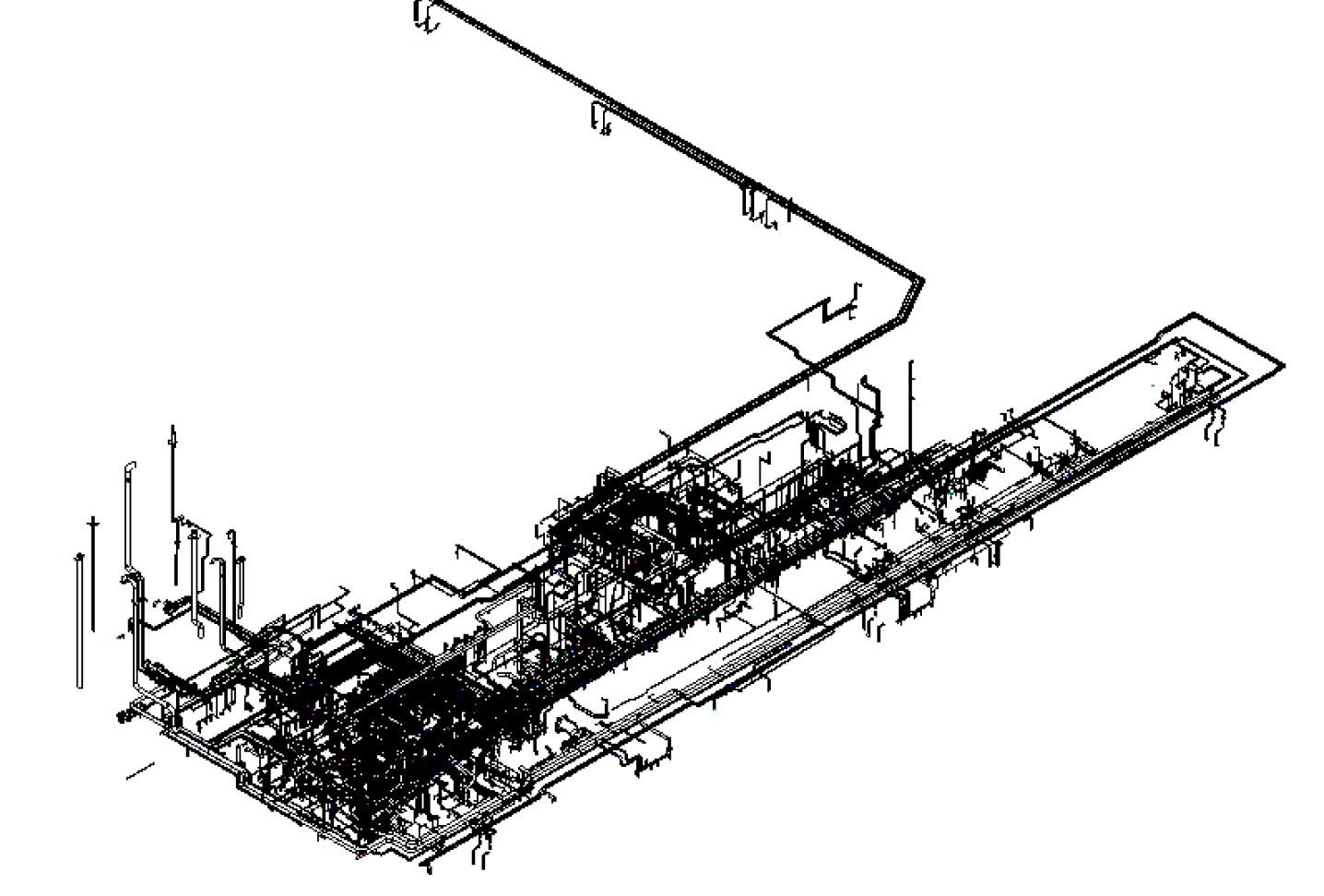

Project Scope and Complexity: This project involves industrial pipework modeling for a paper plant, featuring over 15 diverse systems and encompassing 140,000 linear feet of pipes with diameters ranging from 2-1/2" to 48".

Prefabrication and Precision: Emphasizing prefabrication with a Level of Detail (LOD) 400, the project highlights meticulous attention to detail, utilizing fabrication parts with a tight tolerance of 1/16".

Volume and Efficiency: The project undertakes the fabrication and assembly of over 8000 spools, demonstrating not only the vast scale but also the efficiency of the spooling process.

My rol

As a Project Manager and Technical Lead, my role encompasses:

Client Progress Meetings: Conducting regular meetings to align on project goals and address client concerns.

Work Package Scheduling: Strategically scheduling and managing work packages for efficient project execution.

Modeling Team Coordination: Leading and coordinating the modeling team to ensure cohesive and quality work.

File and Planning Table Management: Overseeing the setup and maintenance of project files and planning tables for optimal organization and tracking.

Technical Problem-Solving: Providing expert solutions for complex technical challenges in the project.

Team Mentoring: Guiding and mentoring the team for professional development and skill enhancement.

The team consists of 2 Senior BIM Specialist, 3 Semi Senior BIM Modeler and 2 Junior BIM Modeler.

Tools

Challenges

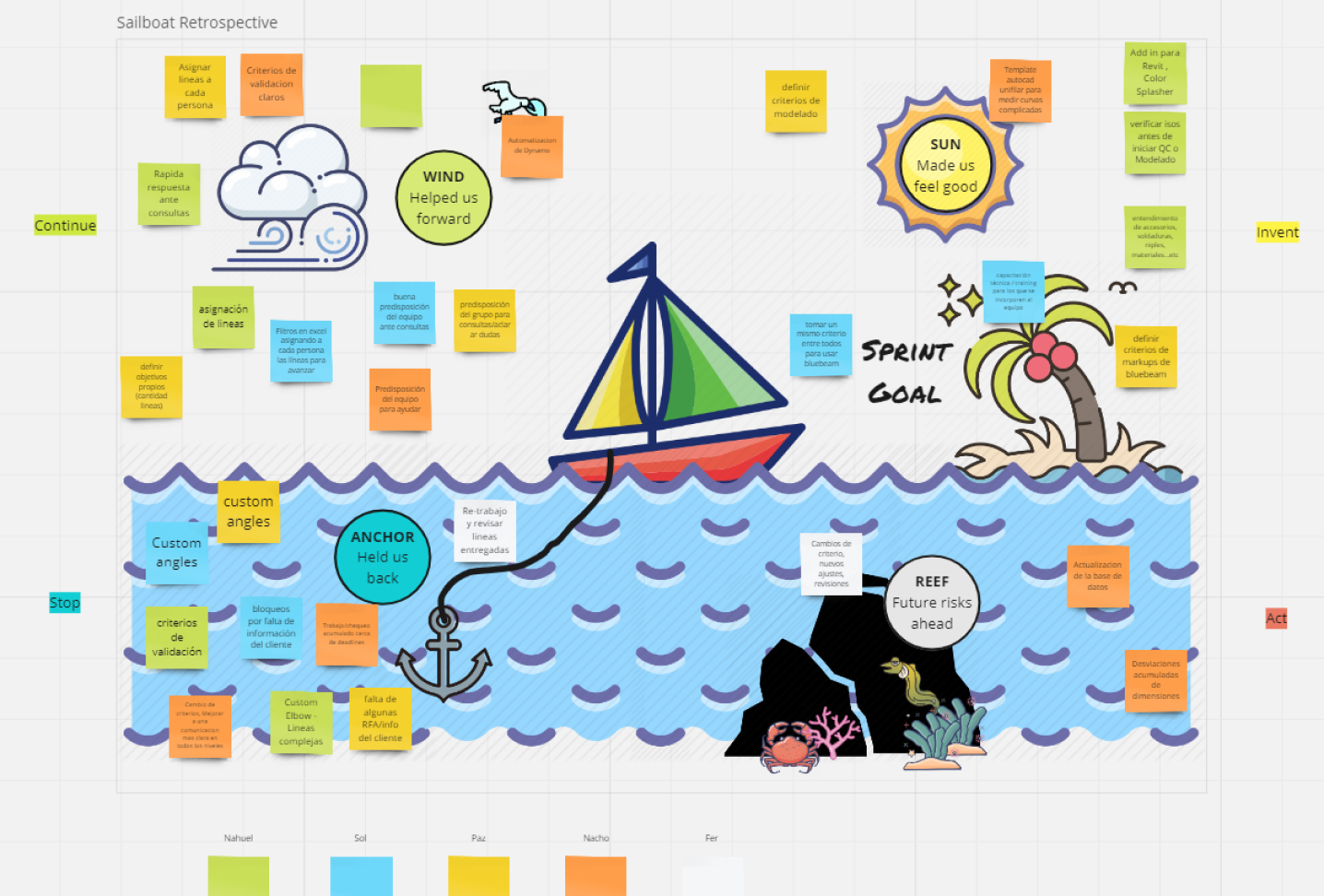

Overcoming New Team Dynamics: Achieved project milestones with a team new to the company, regardless of their seniority. My role involved strong guidance to integrate team members into our company's processes. Post our first SCRUM retrospective, senior members significantly improved the workflow, aiding junior members in overcoming initial obstacles.

Navigating Project Uncertainty: Faced with the challenge of slow information release, I planned the project amidst high uncertainty. Adopting agile methodology was key, providing a clearer view of progress and risks, which led to proactive measures like team expansion to meet project demands.

Precision Under Tight Deadlines: The project required high precision within constrained timelines. This called for several iterations to develop and perfect our QA procedures. Through this process, we not only met our goals but also established a refined and effective workflow for future endeavors.

If you would like to know more about my involvement in this challenging project, please do not hesitate to contact me via LinkedIn.

Also, please note that the graphic content presented respects all confidentiality agreements and is password protected to ensure its proper use. Thank you very much for your understanding.